Ok… So I started writing this part of the Marine Propulsion series about 6 months ago and I haven’t been able to find my grove in regards to writing about slow speed diesel engines. Truth is that I don’t have any experience with these engines and have never really taken much time to study them, but they are the most common engine used in shipping and folks are generally interested in them, so Imma do my best to mansplain what I do know about them.

I’ve had several drafts for this essay but could never get them the way that I liked so instead of trying to make the other drafts work, I scrapped the whole thing and started over. I tend to write like I speak and it’s easier to write this out as the words come to me instead of over time, so here is the next part of the Marine Propulsion series. Just read it out loud with a beautiful baritone southern accent and it will be just as though I’m reading it to you. As before, I am going to limit this essay to how the engine functions as part of the engineering plant and not so much on the technical aspects of the engines themselves. Slow speed engines are the original diesel engine and trying to cover that much technical data wouldn’t be practical for most folks and I don’t know that much about them anyway…

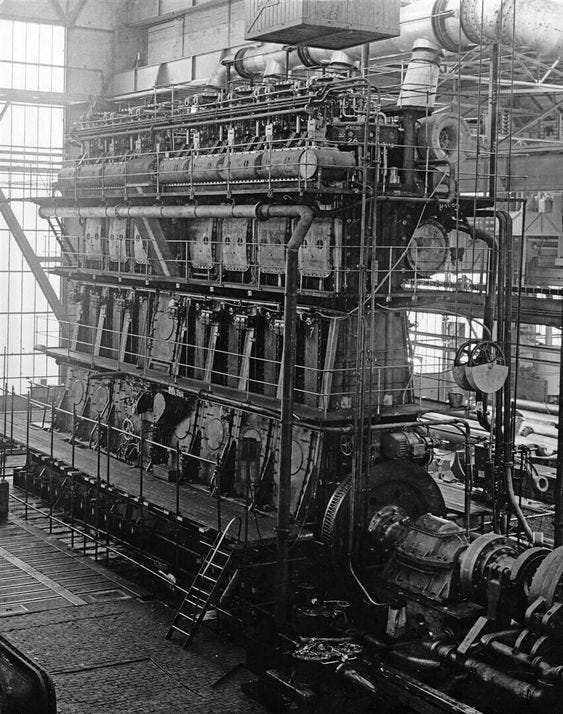

The slow speed engine evolved over time just like every other mechanical thing in history but instead of getting smaller, they became much bigger. Today the Sulzer RTA series engines can reach over 100,000 horsepower and power some of the largest ships ever built.

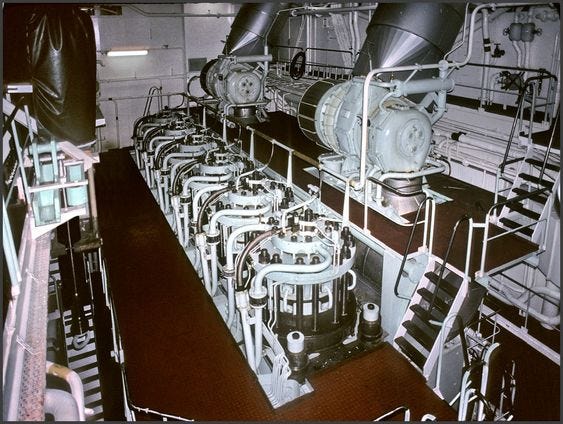

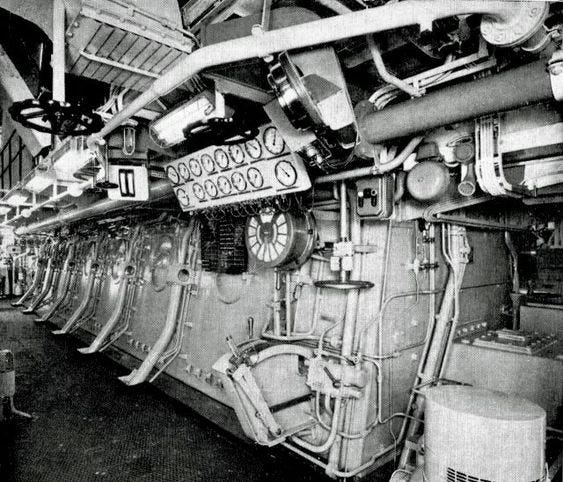

As mentioned, slow speed engines are the most common engine in shipping. Most container ships, tankers, bulk freighters, ROROs, and CONROs are powered by slow speed engines since they are the most economical engine available. These engines have a “slow speed” designation because of their operating speed, which is typically 100 to 120 shaft RPM, allowing large diameter propellers to be used thereby making the most of the slow speed engine’s efficiency potential.

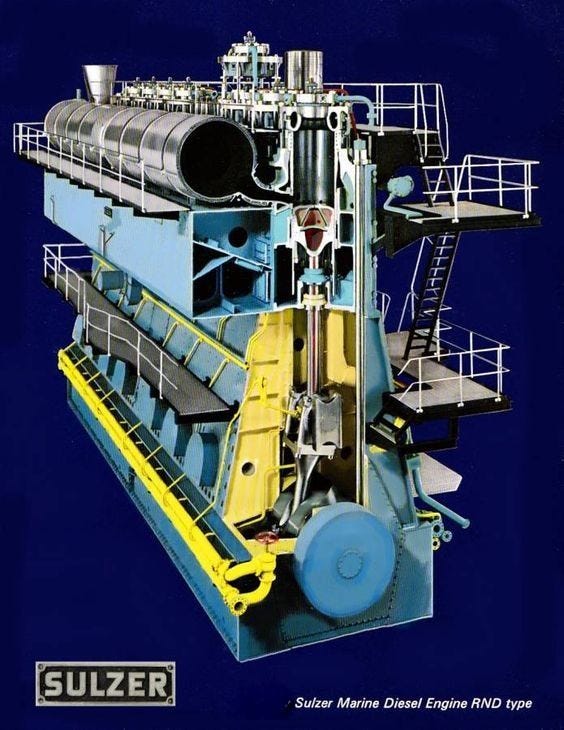

These engines drive the propeller directly, meaning that there is no reduction gearing in the drive line. The engine turns the propeller shaft and the the propeller shaft turns that propeller. In this regard, they operate just like the reciprocating steam engines of old. In fact, the engines have a lot in common with reciprocating steam engines as they were developed from and built in the same shops as the reciprocating steam engines of old.

Now I know your thinking that if the engine is direct drive, then how does the ship change direction? Well I’m glad you asked… The engine itself can rotate the propeller shaft in either a clockwise direction or a counter clockwise direction. So what happens is when the ship needs to go forward, the engine operates in the direction that drives the ship forward. If the ship needs to go backerds, then the engine is stopped and is then started and operated in the other direction.

These engines are started using compressed air through a type of system known as direct air admission starting. The way that it works is fairly simple. On top of each cylinder is a start air valve. When this valve is opened, compressed air is admitted to the cylinder, which pushes the piston down and this turns the crankshaft. This action moves the other pistons up or down and then once fuel is admitted to the engine, the engine begins to run.

In operation, slow speed diesel engines function just like any other two stroke diesel engine and can be loop scavenged or uniflow scavenged in operation. Scavenging refers to the process of supplying fresh air to the engine in order to evacuate combustion gases from the cylinder and to help add fresh air for the combustion process. On smaller engines, this is typically accomplished with a blower that is powered by the engine itself but on these larger engines, this is accomplished with monster sized turbo chargers which use exhaust gas to power a compressor. The compressor in turn compresses (duh..) fresh air and supplies that air to the engine.

Mechanically, these engines operate like the reciprocating steam engines of the past. A piston is pushed downward by expanding gas. That downward linear motion is converted to a rotary motion by the piston pushing on a piston rod which then pushes on a crankshaft, which in turn rotates the propeller shaft. Because of the length of the piston stroke, these engines are built using what’s known as a crosshead. The crosshead allows for the use of a smaller engine housing and crankshaft. This is an interesting way of converting the linear motion of the piston into rotary motion needed by the propeller shaft and is the same method used by the old reciprocating engines.

Below is a series of images that depict the components from the piston to the crankshaft.

Some of the other differences between these engines and their smaller cousins is that the pistons are usually either oil cooled or water cooled. Oil is supplied to all of the rotating parts of the engine, just like any other engine, but the pistons are lubricated using a dedicated cylinder lube oil system. The oil used in this system is used to lubricate the piston as it slides inside the cylinder and is not recovered. It is intentionally used in a way that the oil burns off during the combustion process.

Engine cooling is the same as any other engine. Jacket water (engine coolant) is circulated through the engine and picks up heat as it travels through the engine. The water is then passed through a heat exchanger where the jacket water is cooled using seawater. Used to be that engines were directly cooled using seawater but as technology increased, the engines were cooled using high purity fresh water with corrosion inhibiting chemicals added. Aside from cooling the engine, the heated jacket water is sometimes used as a heat source for the ship’s distilling plant, which is responsible for the creation of fresh water from seawater.

Some vessels have a central cooling system where multiple systems are cooled using a closed loop freshwater system. In this system; engine jacket water, oil coolers, fuel coolers, and intercoolers are all cooled using freshwater that circulates from one system to the next and is ultimately cooled by seawater passing though a heat exchanger.

Unlike smaller engines, the pumps used to operated the jacket water system, fuel system, and lube oil system are all electric motor driven pumps instead of from pumps attached to and driven by the engine itself. For every pump, there is usually a stand by pump that automatically starts in the event of a failure in the main system pump.

For fuel, these engines burn two different fuels; diesel fuel and heavy fuel oil. Typically, they burn diesel fuel when they are leaving and entering port and will switch to burning heavy fuel oil when they are at sea. Heavy fuel oil is the stuff that is left over after crude oil is turned into other types of fuels and is referred to as a residual oil. Its used because the fuel is cheaper than burning diesel fuel. This fuel is thick and needs to be heated to several hundred degrees before it can flow and be injected into the engine. The fuel oil also contains higher amounts of sulfur and due to this, it must be burned away from cities and population centers just to keep the air pollution to a minimum.

The engines are typically controlled from the bridge through direct engine control but they are monitored from a central control room where engine control can be taken from the bridge whenever needed by the engine room personnel. The engines lend themselves to automation and have gone from being mechanically operated to being monitored and operated through computer control. In the older ships, the engines, pumps, and systems were all controlled and monitored locally at each piece of equipment. Nowadays, all of this is done from a central control room.

This concludes the slow speed diesel portion of the “Primer of Marine Propulsion” series. These engines have really revolutionized marine propulsion in large ships. They’ve decreased the number of crew, made the engine rooms smaller, and increased the efficiency of the large cargo ships. From the moment these engines showed up on the scene back in the early 1900’s, the steam propulsion system was on its way out with the exception of high speed vessels. If you have any questions or comments, then please leave them in the comments and I’ll respond as best as I can.

Decades ago I had a friend who wondered if he could make his diesel engine run backwards, like the ships. He had a Mercedes 190D, '50's vintage I think. He put his car in reverse, backed up fast and then shoved it into a forward gear and dropped the clutch (I am fuzzy on these details) but sure enough, he got the engine to run backwards, with smoke pouring from under the hood, the exhaust pipe was now the intake, and he had 4 backward gears and one forward gear. He drove it around for a little bit, then stopped it, none the worse for wear, that we could tell.

Those are some massive machines!

Does the electric generator sets run off of the main engine or do they have aux engines for that?