When I started writing this portion, I started down the path of writing about how a diesel engine works but then I quickly realized that that would be much more than what I initially planned and that writing such a thing would be way beyond the goal of this post. So I am going to keep this as general as I can, for brevity and because the more I write, the more people might realize that I don’t know what I’m talking about… There is tons of information about how a diesel engine works and they all basically work the same way, so I’ll leave the operation out of the discussion and just mansplain how the engine functions as part of a propulsion plant.

So let’s proceed with the proceeding…

As before, let’s start out with a little bit of history… The late 1800’s was a period of some really rapid advances in mechanical engineering and engine technology. Kinda like today with the electronic and computer technology that is leading us to a future somewhere between The Matrix and Terminator…

The internal combustion engine was first developed in the 1860’s and development progressed rapidly. Starting with engines that burned gaseous fuels, then on to engines that burned liquid fuels, such as benzine, and then finally on to fuel oil, which today generally refers to diesel fuel and kerosene. The earlier engines used an electrically created spark to generate the heat for combustion of the fuel and are known as spark ignition engines, which is how gasoline and natural gas engines operate today. Though much more complex so far as technology is concerned, gasoline and gaseous fueled engines work the same way today as they did in the late 1800’s.

Then came along the idea of heating air to incredible temperatures using compression of air to form the ignition source for the fuel. The idea wasn’t really new. It was known for centuries that compressing air can create tremendous amount of heat but the idea of using that heat to ignite fuel was the new idea.

Rudolph Diesel is widely regarded as the inventor of the compression ignition engine but that is incorrect. There were a few folks that were developing the technology at the same time and he was the first guy to get one to run under it’s own power so he gets the credit of developing the engine. His original idea was to use coal dust as a fuel source but changed his mind when his engine exploded and injured some folks, including himself. Eventually, the bugs were worked out of the design and now the diesel engine is the most popular and most efficient engine on the planet and will be for the foreseeable future.

The first marine use of the diesel engine was by the French, who figured out that putting a diesel engine in a submarine was much more gooder and safer than the gasoline engines that were being used at the time. Commercially speaking, the first use of a diesel engine for ocean going marine propulsion was in the tanker Vulcanus, built in 1910 for Shell Oil and from then on the diesel engine became the main challenger of the steam engine.

Diesel engines became commercially popular from the beginning of their introduction as a viable form of power generation and propulsion and for good reason. As compared to a steam plant, the entire diesel engineering plant is simpler, requires far fewer crew to operate, is more efficient, requires far less time to bring on line, allows for greater freedom in design, requires less attention to operate, and offers better maneuverability than the steam plant ever could. The more conservative ship owners would stay with steam for another 50 years or so but the writing was on the wall for the steam plant as used in commercial vessels. Naval vessels would hold on for a while because Navies tend to stay with what works but eventually Navies with budget limitations and common sense moved towards the diesel engine or combined engineering plants, which diesel engines are still a part of.

There are a number of ways to classify the different engines:

Operating speed. Slow speed (below 200 RPM), medium speed (200-1000 RPM), and high speed (over 1000 RPM).

2 stroke cycle or 4 stroke cycle.

Inline configuration, V configuration, Opposed piston.

Single acting or double acting.

Supercharged (blower), Turbo-charged, Naturally aspirated.

I’m sure there is something that I am forgetting so Imma add number 6 in memory of the forgotten.

As mentioned above, I want to keep this kinda general as this is a topic in which volumes of books have been written over the last 100 years and so I am going to limit this discussion to medium speed engine powered vessels and high speed engine powered vessels. Slow speed engines will be detailed in a follow up post as they function somewhat differently than the medium and high speed engines and really require a section of their own.

Typically, medium and high speed engines are used on smaller vessels but are also found on large vessels where there is limited available space for engine installation or have requirements for flexible power generation and use or on ships that require higher operating speeds. Cruise ships, landing ships, naval support vessels, and RO/RO ferries are some typical examples of larger ships that use medium speed engines for propulsion. Offshore supply vessels, IMR vessels, various naval and coast guard vessels, and research vessels can have high speed engines that provide propulsion though a diesel-electric arrangement.

There are several different engine configurations utilized to make the propeller go roundy-roundy. Depending on the power requirements, a single engine could be used to turn the propeller, multiple engines can be coupled together through a reduction gear to turn a propeller, multiple engines could be used to operate generators which in turn power electric propulsion motors, or they could be part of a combined plant in which a gas turbine engine and diesel engine are operated together in order to make the best of use the operating characteristics of both types of engines. This is usually used in Naval ships.

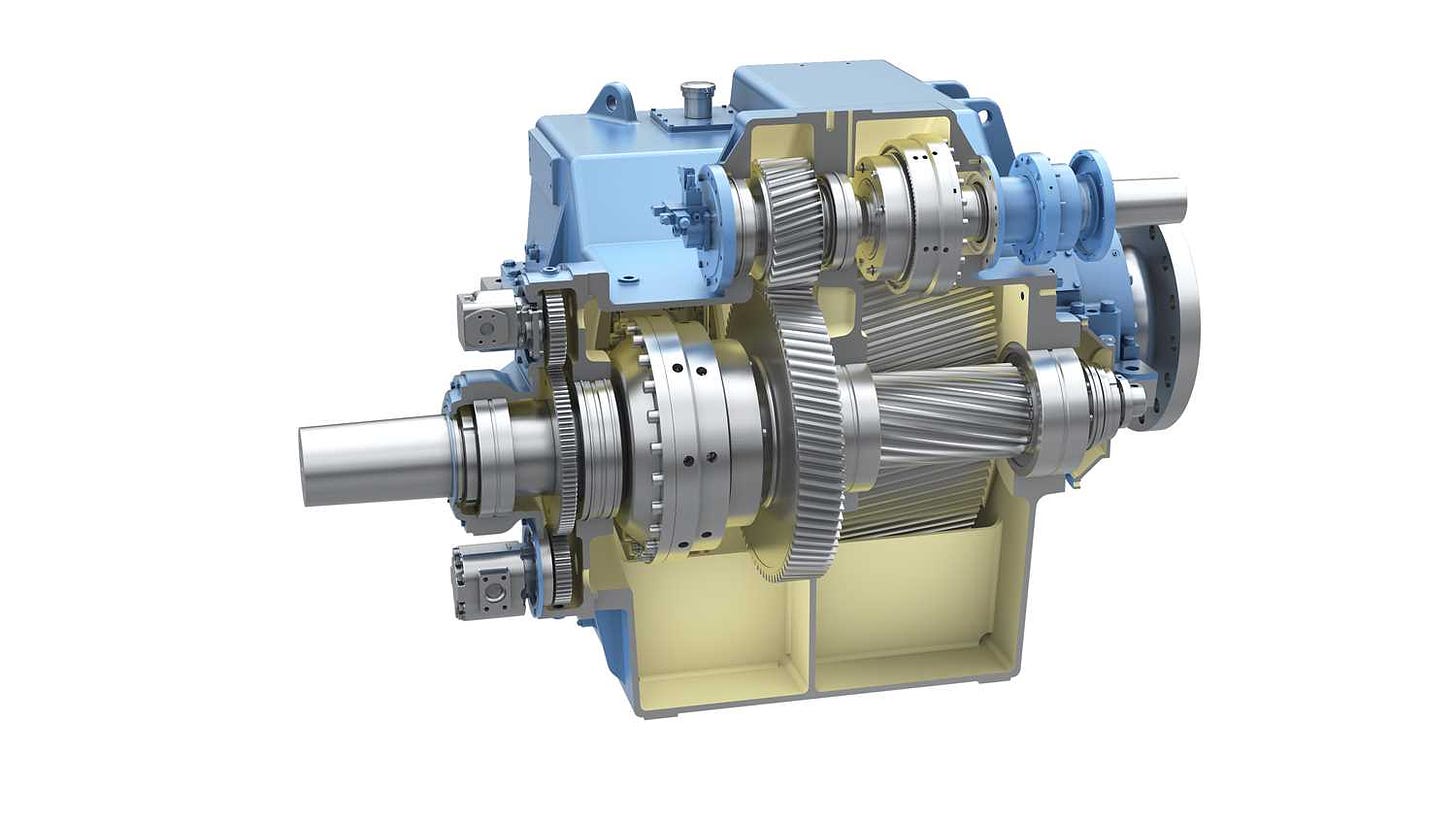

For vessels where the engine directly drives the the propeller and depending on the speed requirements of the propeller, the engines may be directly coupled to the propeller shaft or through a reduction gear, which functions much like the transmission in your car. There aren’t many direct drive medium speed powered vessels anymore due to that fact that in order for the vessel to reverse direction the propeller needs to turn backwards and if the engine is directly coupled to the shaft then the engine would need to be able to reverse direction as well, which was the way that it was done back in the day and is how it is still done with slow speed engines. Modern engines aren’t designed to rotate in both clockwise and counter clockwise directions, they are designed to be operated in one direction only, so there must be a way to change the direction of shaft rotation in order for the vessel to reverse and go backerds and that is done through what’s known as a reduction gear.

Reduction gears are where engine speed is reduced to match the performance requirement of the the propeller and is where the reverse gearing and clutches are installed. A medium speed engine may be able to produce well over 3000 horse-power and turn at 1000 RPM but a propeller that is 6 foot or so in diameter may only be able to efficiently operate at a speed of 300 RPM, so in order to make that happen, the speed of the shaft must be slowed down and this is accomplished in the reduction gear.

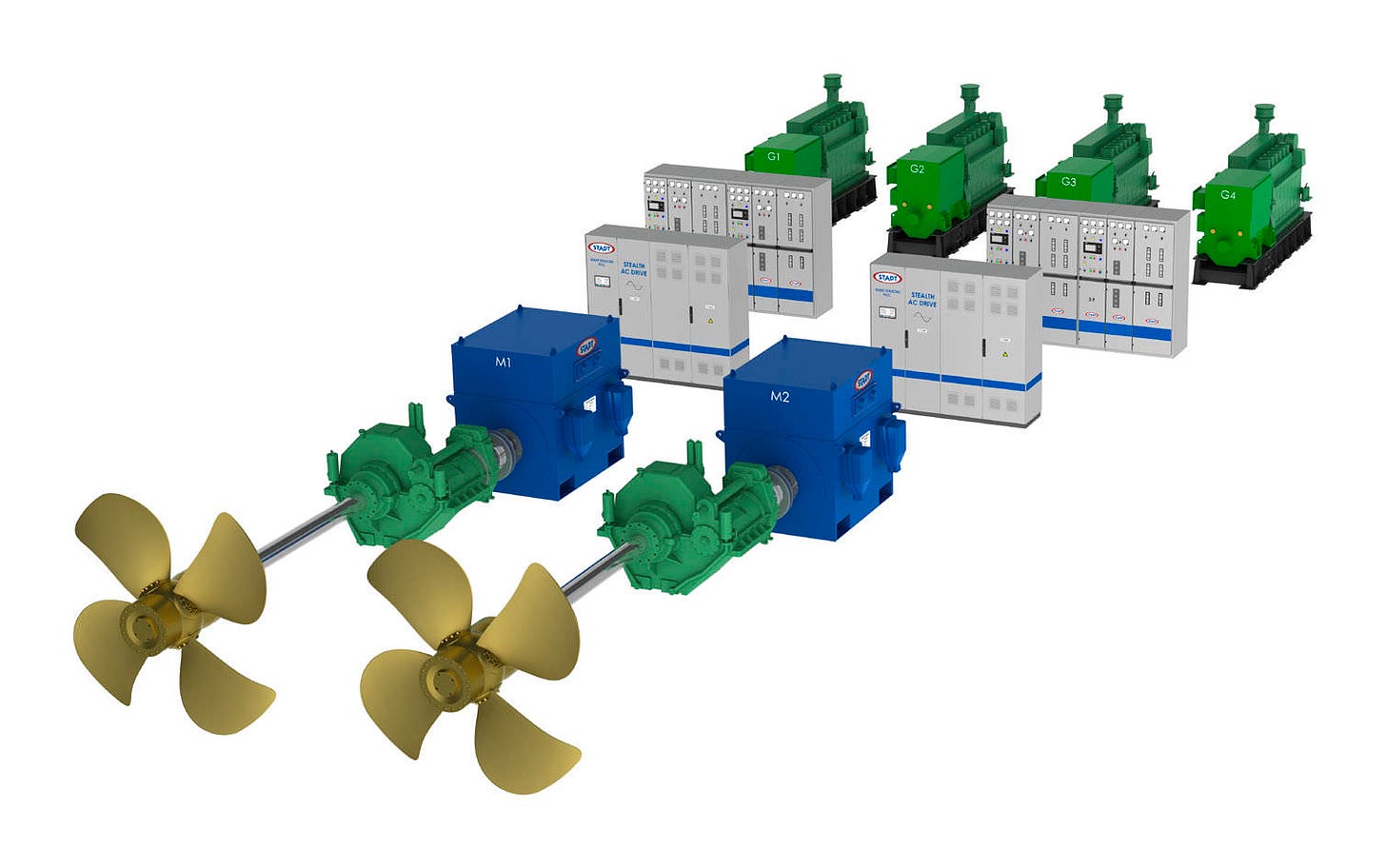

This kind of arrangement is so last century and is pretty much out of style. What’s in vogue these days however is the diesel electric propulsion arrangement, where several engine driven generators are used to power propulsion motors, which then drive the propeller or propellers. This allows greater flexibility in the design of the plant as well as greater operating efficiency since only the amount of power needed is generated. By utilizing several smaller generators instead of one or two larger generators, power generation can better match the demand. This allows for better fuel consumption, less noise and vibration, smaller and easier to repair engines, and increased redundancy. Overall, this configuration is far more gooder than what has been used in the past and will be the standard propulsion arrangement for the foreseeable future.

So how does the diesel-electric plant make the propeller rotate? I’m glad you asked… Essentially what happens is that the electricity produced by the generators is used to power an electric motor which can be coupled to the propeller directly but is usually connected to the propeller through some form of reduction gearing. The image below illustrates this system quite well. Power is generated by the generators, then sent to switchboard where the electrical power is distributed. From the switchboard, power is sent to the propulsion motor drives, which house the motor controlling electronic wizardry, and then on to the propulsion motors themselves. Speed and direction changes are made through either the propulsion motor drive, typically a variable frequency drive, or through the use of a controllable pitch propeller, or a combination of the two.

Just thought to add this bit… Diesel electric propulsion is nothing new and has been around since the diesel engine has been a thing. Until nuclear power was used, submarines have always been, and many still are, propelled by diesel electric systems. As steam died out in the tugboat world, many tugs were converted from reciprocating steam engines to diesel electric, especially after WW2 when the engine market was flooded with surplus diesel engines, generators, and propulsion motors. The main difference between back in the day and today is that DC power was utilized back in the day as DC is fairly easily controllable. Today, there are very few DC powered vessels steaming around. As technology has progressed, AC power is now widely used.

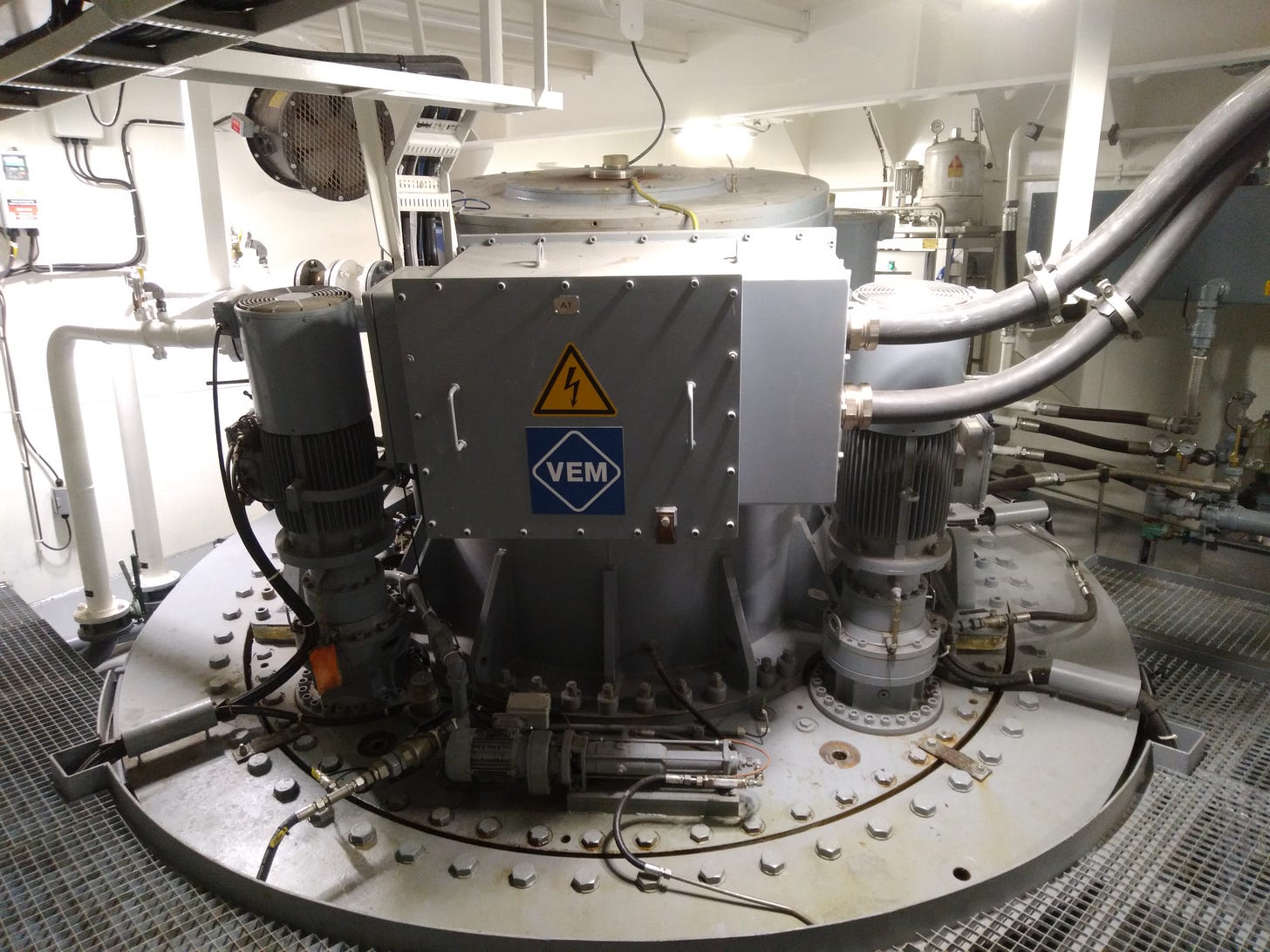

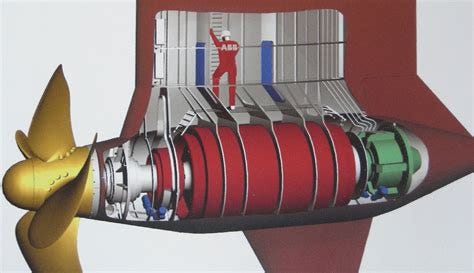

The more conventional diesel-electric configuration has given way to more efficient arrangements. Today, Z-drives and azimuthing pods, or Azipods as they are known, rule the seas. These systems are rather interesting in that they do away with the traditional rudder and swing the propeller through 360 degrees of movement, much like a trolling motor on a fishing boat. This greatly increases the maneuverability and station keeping of the vessel.

The main difference between a Z-drive and Azipod is the location of the propulsion motor. In the Z-drive system, the motor is mounted inside the vessel and in the Azipod, the motor is mounted outside the vessel in a large pod.

To illustrate this, I jacked some images from the interwebz and included some of my own. The images explain this far better than I could.

So in conclusion… this concludes the medium and high speed engine portion of the discussion on diesel engines as used in marine propulsion. Next up is the slow speed engine, which is what I believe most people are curious about. Let me know what you think in the comments. I’ll do my best to answer any questions that you have and as always, if I can’t get you an answer then I’ll just make up something that sounds good. Have a blessed day.

Kind Regards,

Nate

A subject I didn’t even know I was interested in! Very nice!