The first steam powered vessels were small vessels that traveled inland waterways as paddle boats. These came about in the late 1700’s. The first steam ship to make it across the Atlantic was named Savannah and it traveled from the east coast of the US to England. Ships couldn’t carry enough fuel to make it all the way across without sail so the first steam ships used sails and steam, steam mostly for going up river, maneuvering in port, and during periods of low winds. As technology improved, steam pressure was increased, which increased efficiency. Towards the end of the 1800’s, ships were able to sail across the Atlantic without the use of sails, even though they were still built with masts and rigging for sails.

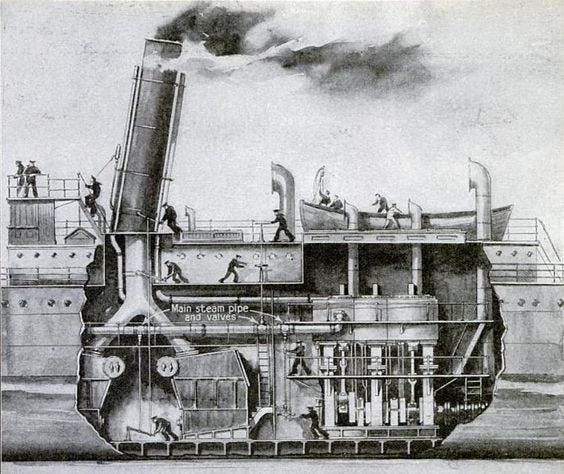

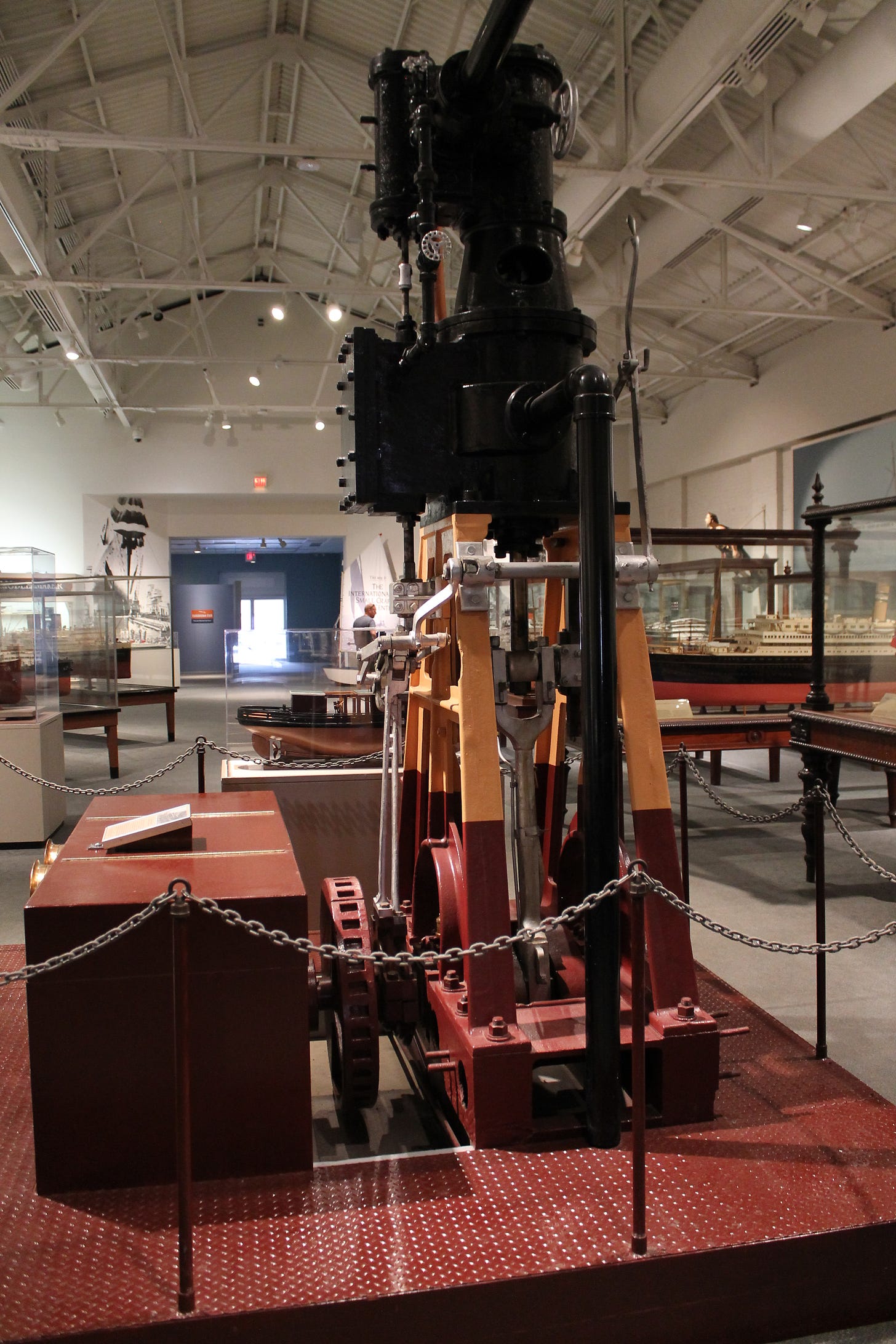

The principle steam engine utilized, until the 1940’s, was the reciprocating engine. There was a metric butt ton of variations and designs for single cylinder engines in the beginning but multiple cylinder engines started being built once it was understood that more energy could be extracted from the steam if it was allowed to expand in several steps, or stages. Allowing steam to expand across several steps became known as compounding. Compounding, along with increases in technology, allowed for higher pressures to be created which increased the efficiency of the system. The higher the pressures meant that more heat was being used from the fuel that was being burned.

The first compounded engines were 2 cylinder engines, simply known as compounded engines, which then gave way to the 3 cylinder engine, known as the triple expansion engine. Eventually, this led to the development of the quadruple expansion engine. The quadruple expansion engines didn’t become as popular as the the triples. They were more efficient than a triple expansion engine but pressures and temperatures at which these engines operated put them in competition with steam turbines and the turbine was a far more efficient engine and took up less space that the reciprocating engine.

Around the time that the Quadruple Expansion engine was being developed came the development of the marine steam turbine. Dude named Charles Parsons from England designed and built the first marine turbine and installed it in a small experimental vessel, named Turbinia.

The small vessel had three turbines and was capable of traveling over 30 knots, which was unheard of at the time. Well… since it worked so well, Parsons approached the British Navy about his new technology and was denied due to the initial developmental problems. So he did what anyone would do. After perfecting the technology, he waited for a naval parade, known as the Naval Review, and he drove the Turbinia through the parade at 34 knots. Needless to say, this caught the attention of the Crown and Parsons turbines became the new technology that revolutionized marine propulsion. This event was the beginning of the end of reciprocating steam engine as a form of propulsive power for ships. Today, Turbinia is on display at the Newcastle Discovery Museum in Newcastle Upon Tyne in Great Britain.

So with this conclusion of a very brief mansplaining of steam ship history, lets get into how the dern thing works…

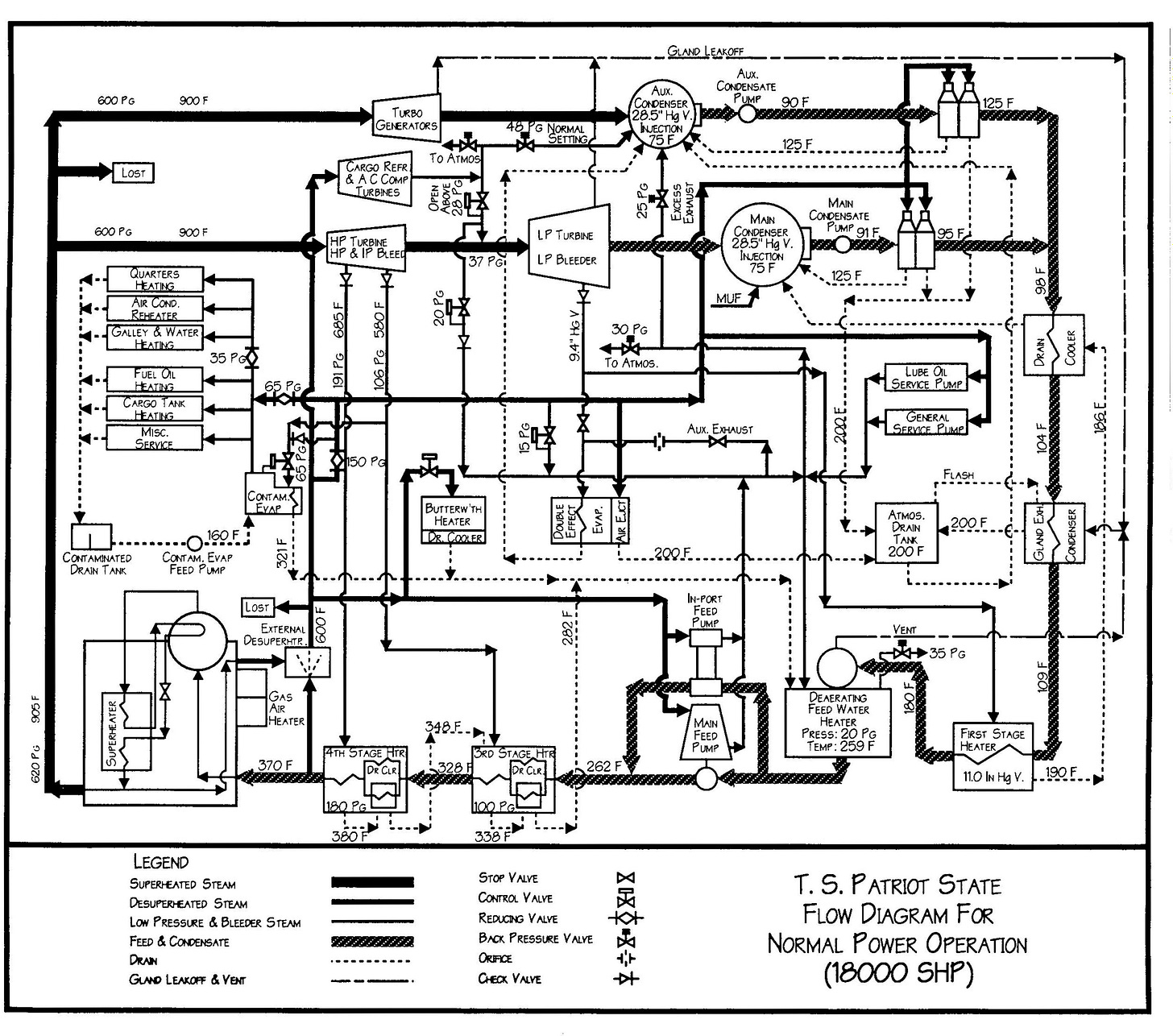

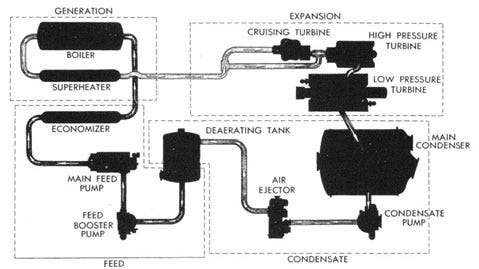

Simply put, a steam plant is a continuous cycle. Heat is add to water in a boiler. The water turns into high temperature and pressure steam. The steam is piped to an engine where it is allowed to expand across several different stages, which converts the heat energy into mechanical energy to drive the propeller. Once the steam has given up all the heat that the engine can convert, the steam is turned back into water where it is pumped back into the boiler and the cycle is repeated.

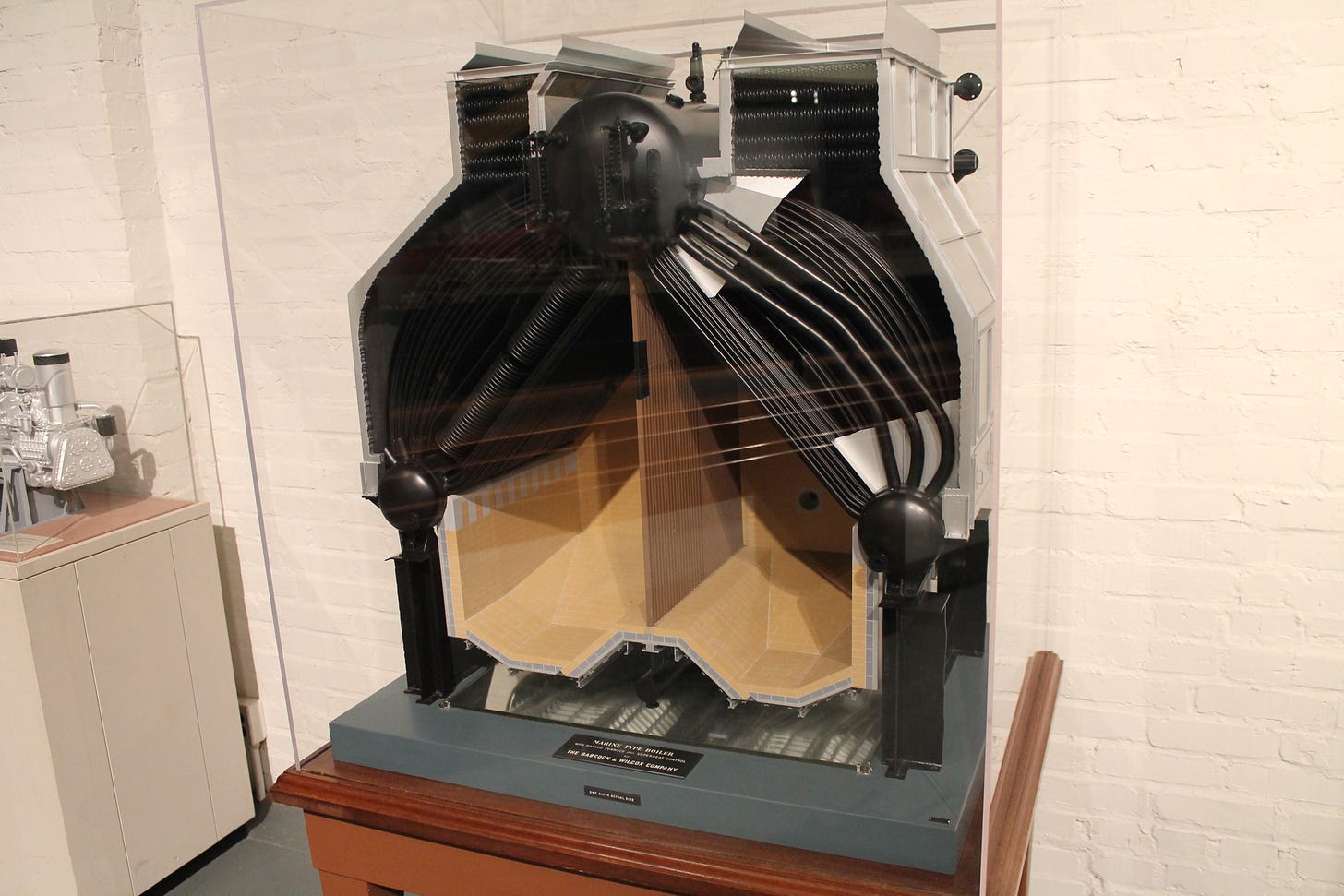

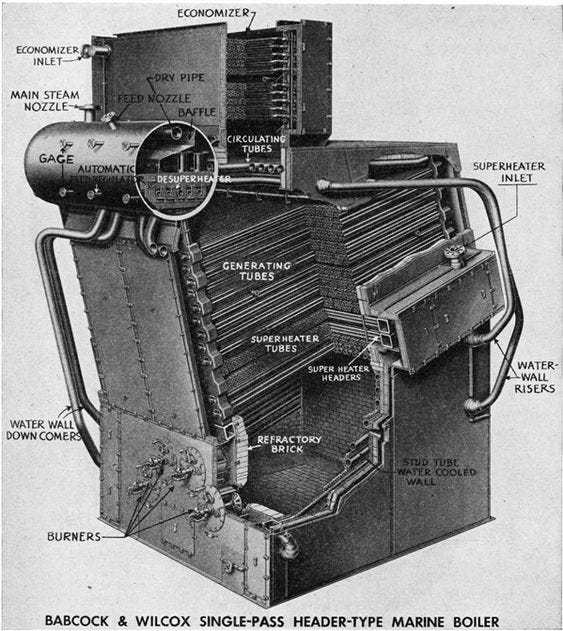

So lets get a little deeper into the major parts of the steam plant, starting with the boiler.

Boilers are pressure vessels where water is converted into steam. Steam is water that has been turned into a gas who’s volume has been expanded 1700 times, holding tremendous amounts of energy. By keeping the steam from escaping and allowing pressure to build, the boiling point of the water is increased. The more heat that is added, the higher the pressure. The higher the pressure, the higher the efficiency and the higher the amount of power that can be extracted. Once the desired pressure is reached, the steam is allowed to flow to the turbine. Depending on the speeds required, the steam may be “superheated”. This simply means that additional heat is added to the steam once it has been converted into it’s gaseous state.

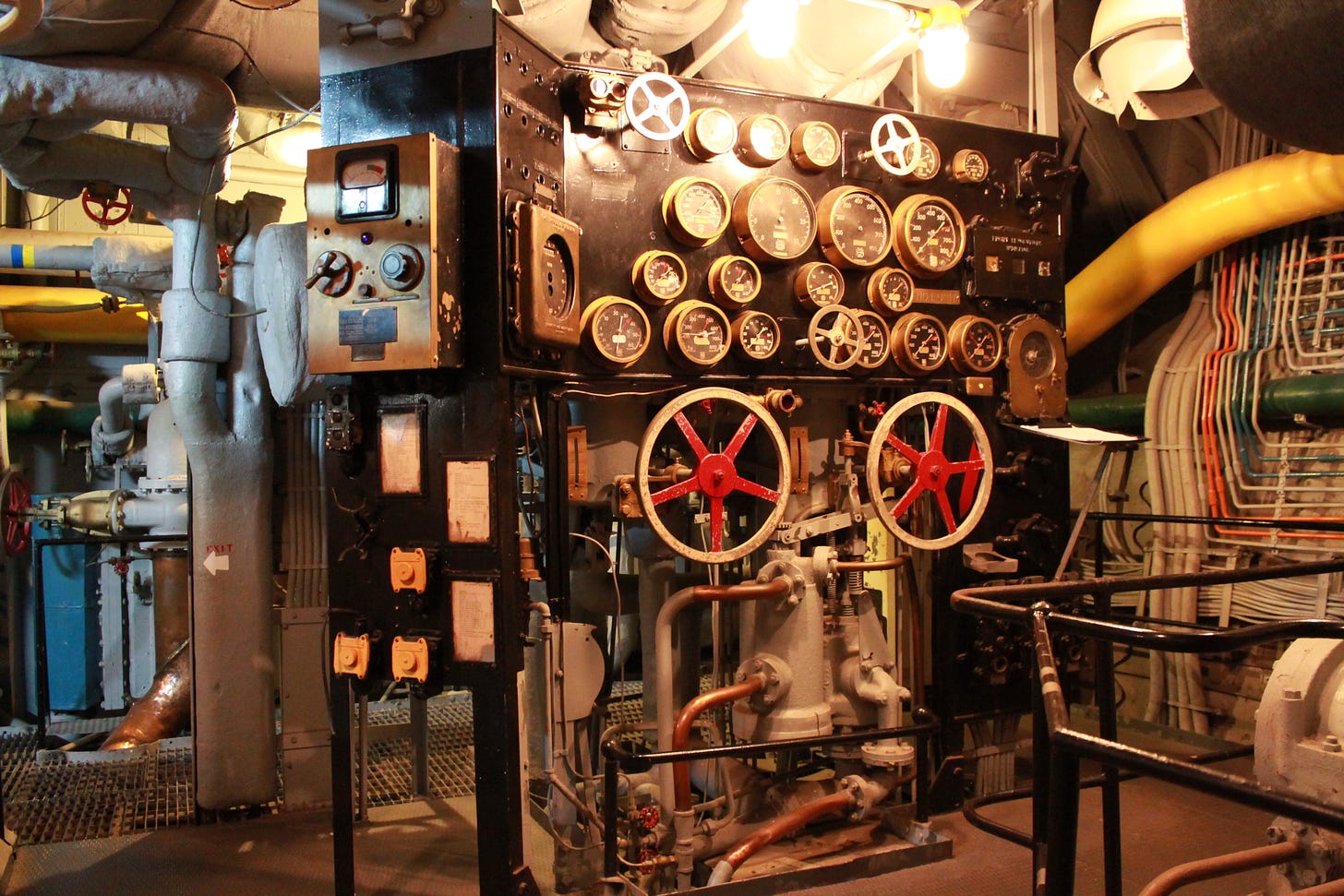

Once the desired pressure is reached, steam is put to work at a controlled rate. The rate that steam is applied is controlled through throttle valves. Admitting too much steam to fast will draw to much water from the boiler and could cause a situation known as “carry over” where liquid water is admitted into the system. Water travels through a steam system at a high rate of speed and can cause damage when it hits something. Steam being admitted to slowly is wasteful in that fuel is being consumed but work isn’t being accomplished in a useful way. Reacting too slowly to throttle changes could cause dangerous situations while maneuvering in port or at sea so throttle changes are done at a controlled rate. The person operating the throttles will adjust the throttle valves based on pressure changes as well as experience. If he opens the valve too fast, steam pressure drops which could cause some severe consequences as well as him being yelled at by the Fireman and/or Watch Engineer, if serving on a merchant ship, and by the leading Boiler Tech (now Machinist Mate), leading Machinist Mate, and/or the Engineering Officer of the Watch (or possibly all three at the same time) if serving on Navy ships. If he opens it too slowly then he gets yelled at by the previously mentioned folk as well as the bridge. Between pressure gauges, experience, machinery sounds, placards, and angry dudes yelling at you… there is always indicator in the engine room to tell you when you’re doing something wrong.

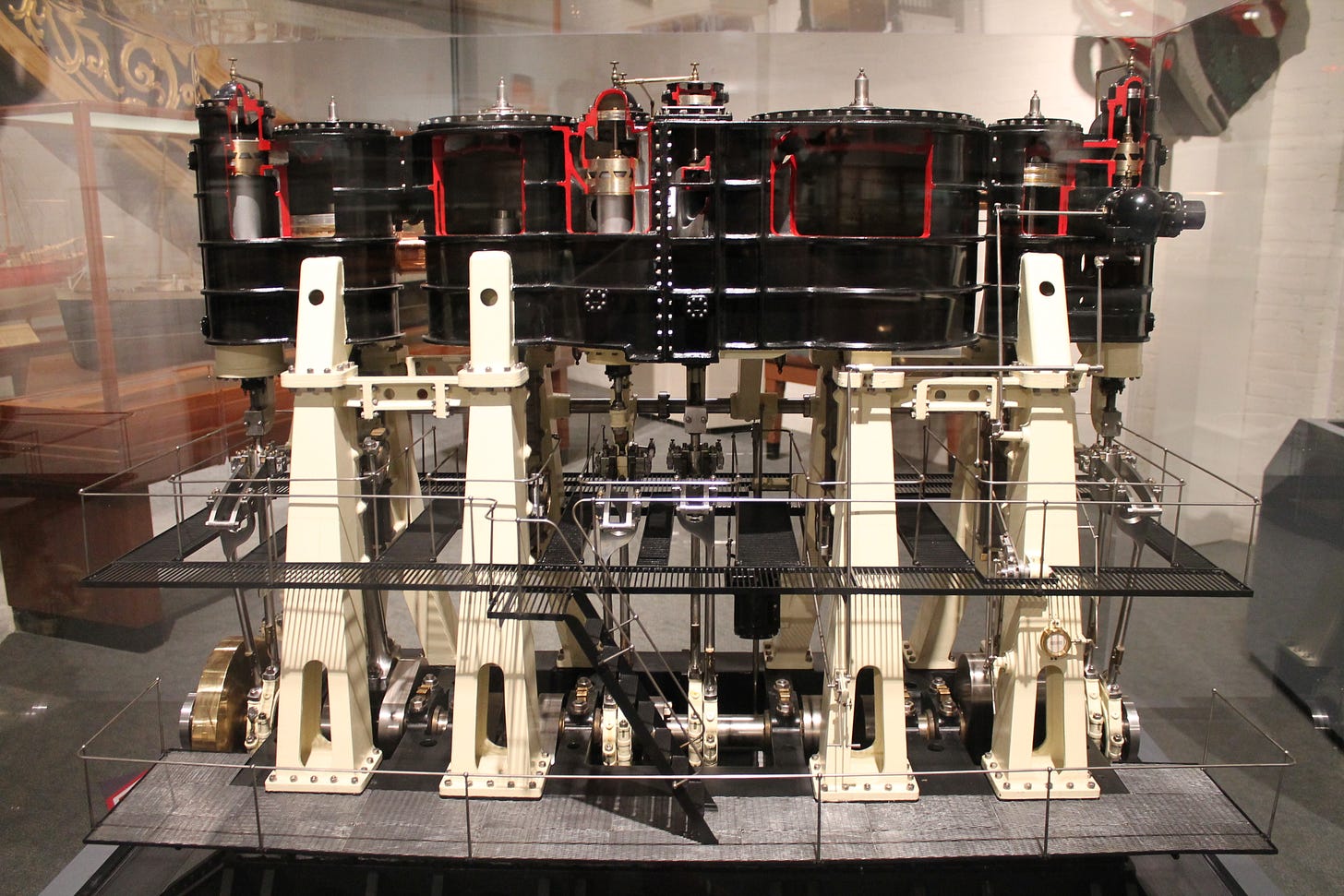

Creating huge amounts of steam is pointless unless there is some work to be done and on a ship that’s done in the engine (duh…). Nowadays, marine propulsion is accomplished through steam turbines, with the exception of a handful of active museum ships. Turbines really gained wide use during WW2 with the development of large gear manufacturing technology and refinement of techniques for the manufacturing of the turbines themselves. Reciprocating engine manufacturing pretty much stopped at that point and was over by the 1950’s.

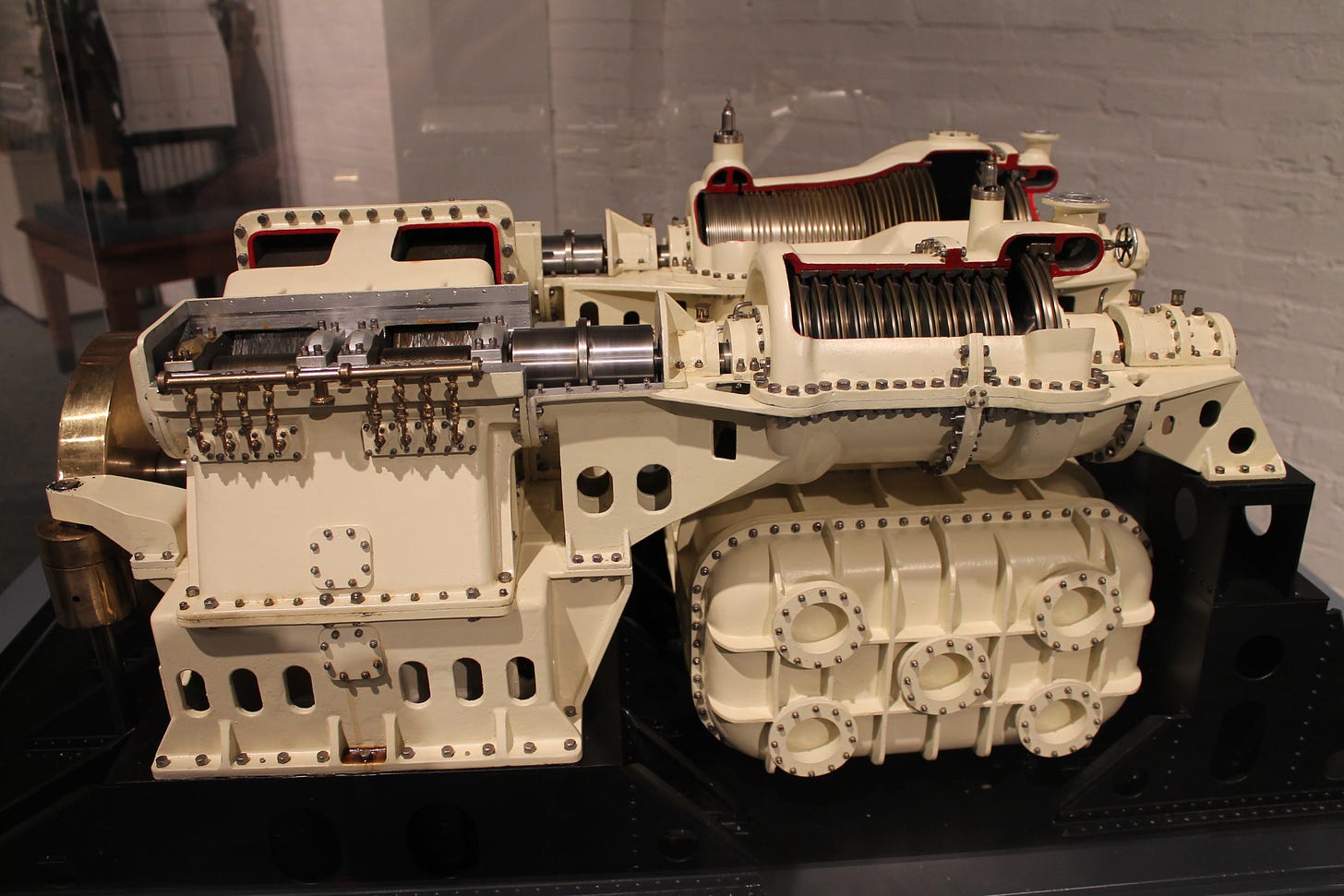

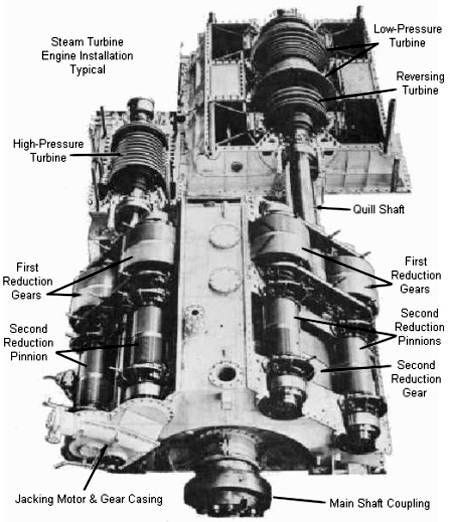

Each “engine” consists of three, possibly four, turbines and the main reduction gear (MRG). The MRG functions as a transmission for the ship. Turbines operate at high rates of speed and that speed must be reduced to a lower rate so that the propellers can operate efficiently. If a propeller spins to fast in water, then it causes cavitation. Cavitation causes damage to the propellers and vibration which in turn causes other problems. So the reduction gear is speed reducer of sorts.

The three turbines installed in this engine are the High Pressure Turbine, Low Pressure Turbine, and the Astern Element. Just like the reciprocating engines mentioned above, steam is expanded across many stages and because of the higher pressures of steam used on turbine ships, more stages are required in order to get the most use out of the energy that has been add to the steam in the first place.

Reversing a steam ship is done by the Astern Element. This is a separate, smaller turbine that is built on to the shaft of the low pressure turbine. Looking back to that imagine of the throttle board above, there are two large valve handles. One handle is for admitting steam into the high pressure turbine, which then flows to the low pressure turbine which rotates the shaft in the ahead direction. The other handle is for directing steam to the Astern Element. To go in reverse, one valve is closed and the other opened and steam is directed to the Astern Element which rotates the propeller shaft in the astern direction.

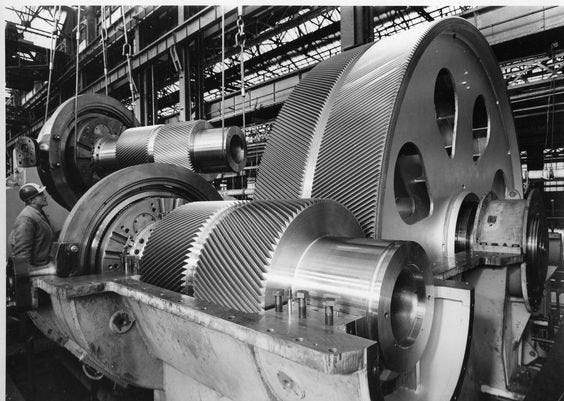

The main reduction gear of a steam ship is used to reduce the speed of the turbines to a speed that is useable by the propeller, as well as increasing the torque, or rotating force, of the turbines. They are double input gear boxes; one input from the high pressure turbine and one input from the low pressure turbine, and have a single output, that being the propeller shaft. MRGs for steam ships are usually double reduction, meaning that speed is reduced through two stages, and are built using double helical or herringbone gears. The input speeds could be several thousand RPM but the output speed is usually well under 200 RPM.

Once the steam is used up, it goes to the condenser where it is converted back into water. Condensers on steam ships use seawater to remove whatever heat is left in the steam, which then turns the steam back into water. Condensers operate under a vacuum in order to extract all available heat from the steam. Water boils at different temperatures based on the pressure acting on the water. The lower the pressure, the lower the boiling point of water and vice versa. For instance, water boils at 80 degrees when in a 28.92 inch of mercury vacuum and it boils at 545 degrees when at a pressure of 1000 PSI. So in order to extract the maximum available amount of heat from the steam, the final stages of the low pressure turbine actually operate under a vacuum, which is generated in the condenser.

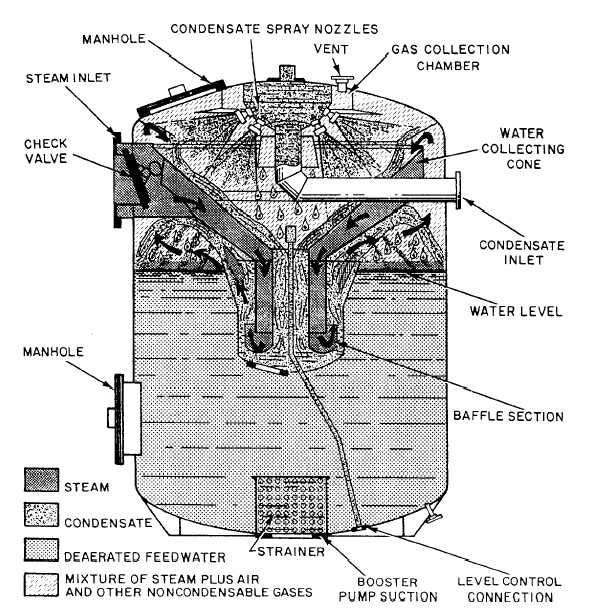

Once the steam is condensed back into water, it collects in the bottom of the condenser, it is then pumped to the Deaereating Feed Tank where any dissolved oxygen and gases are removed. The water is stored here until needed for the boiler and the cycle is continued until the plant is shut down.

This, in a nut shell, is the basic operation of a marine steam plant. As mentioned previously, these systems are fairly rare nowadays, having been replaced by the diesel engine, which is where we are going in the next part of the series. I hope that you enjoyed this brief explanation. If you have any questions then please feel free to ask and I will answer the best that I can. If I don’t know the answer then I’ll just make up something that sounds convincing…

Thanks for spending your time. If this kind of thing is of interest then please consider subscribing. Have a blessed day.

Kind Regards,

Nate